|

|

|

|

Vantec Cu CCK6035D Vs Al FCE 6030D Vantec Cu CCK6035D Vs Al FCE 6030D

|

|

Date Posted: Jul 27 2001

|

|

Author: Joe

|

|

|

|

|

Posting Type: Review

|

|

Category: Air Cooling Reviews

|

|

Page: 1 of 2

|

|

Article Rank:No Rank Yet

Must Log In to Rank This Article

|

|

|

|

|

Note: This is a legacy article, imported from old code. Due to this some items on the page may not function as expected. Links, Colors, and some images may not be set correctly.

|

|

|

Vantec Cu CCK6035D Vs Al FCE 6030D By: Joe

|

|

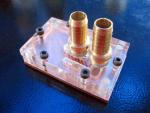

Vantec Aluminum FCE 6030D Vs Vantec Copper

CCK 6035D HSF Comparison

|

|

The second run of the ProCooling testing methodology is here. This is the final test before the waterblock roundup happens on the site soon. Taking

the the method used in in the SK6 Vs Cool Innovations test, and the changes made in testing for the "Autopsy of a Review", I think we have a solid testing setup.

We are going to compare the 2 latest HSF's from Vantec against themselfs. There is little in common, and there is no doubt which one is better than the

other. Ones Cu,and ones Al. But the real interesting thing will be how different the 2 HSF's are and how they compare against an SK6 - the so called top HSF available. KDComputers had these to test and I thought it would be an interesting test of 2 different metal HSF's that are somewhat of the same construction and see how they fair.

Lets look at our contenders:

|

|

Vantec Copper CCK 6035D

|

|

|

|

|

|

|

Specs:

Weight: 386.0 (gm)

Full Size: 65.0 x 64.0 x 39.0

Fin Size: 1.25"Tall 1.36" Long

Fin Count: 34

|

|

|

|

|

|

This is Vantec's current flag ship HSF.

This is meant for the current 70+watt Athlons on the market. their all Cu construction makes them very good at moving the heat away from the core and to its .25mm thin fins. The HSF's construction is similar in a few ways to the ThermalRight SK6 as it uses a similar interlocked fin setup. The fins on

|

|

this HSF are much longer than the thermal right and also are much taller.

They also appear to be soldered in the same fashion to the copper base plate. The big separator from the SK6 is its Al. "hood" that goes over the HSF. This functions on 2 levels, 1. it gives an easy mounting for the fan, and 2. it offers a air duct keeping the air moving the direction it should. This gives the HSF a unique look over its predecessors with its brownish red anodized Aluminum hood. The HSF comes stock with a Delta 7200 RPM fan and finger guard. (hehe I think OSHA requires these guards on the 7200 rpm fans, along with a set of ear plugs hehehe j/k :) The bottom of the HSF was a clean and smooth flat Cu surface. It wasn't as nicely milled as the SK6 but it was better than most others.

|

|

|

|

Vantec Aluminum FCE 6030D

|

|

|

|

|

|

|

Specs:

Weight: N/A

Full Size: 59.0 x 60.0 x 27.0

Fin Size: 1.81"H 1.06" L ( long fin's) 1.45"L ( short fins)

Fin Count: 96

|

|

|

|

|

|

The smaller sibling to the 6035D above, is the FCE 6030D, this is an Al. counter part to the Cu HSF.

In basic looks, it looks similar, but there is quite a few things different with this HSF besides for its materials. The first big one is its size. Its small, 5/16" shorter than the 6035D. Also the air flow is opposite from the 6035D. The clip runs the other direction across the HSF perpendicular to the fins, in some case / mobo setups this will allow the fan to breathe better.

The fins are nicely laid out and the overall construction quality of this HSF is top notch. The same Al. hood as the Cu one provides a nice

mounting surface as well as points

|

|

|

|

the air in the right direction. The Base of the HSF was not really well polished at all. It was smooth but it could use a quick rub with some 1500

grit sand paper. The base was still smoother than most of the Aluminum HSF's out there.

The Clip is ok, it gets a little tight to install on a KT7A/E I found as the back clip needs to be pushed down onto the back lug as well as the front one as normal. Only area I would improve both the clips on the 6030D and the 6035D is to make them 3 tooth clips that will attach to all 3 lugs on the socket ( socket A) or the 2 on each side that the Socket 370 have. This HSF also comes with the Delta 7200 RPM and safety cage.

|

|

|

|

|

|

|

Testing Setup-

|

|

|

As I outlined in the "Autopsy of a Review" article, the testing is being carried out on a

testing modified AMD 1.4GHz AYHJA-Y CPU. The CPU is being run at 1.533Ghz @ 1.85Vcore giving an effective heat load at full CPU load of around 87 watts. Props go out to KDComputers for helping us with this

core. Heck they even saw what I was going to do to it and still gave us one! ;) Same can't be said for AMD them selfs.... wussys...

|

|

|

|

|

|

|

|

|

|

CPU

|

ThunderBird 1.4Ghz@ 1.53GHz @1.85VCore

|

|

Ram

|

Crucial 256mb PC133 CL2

|

|

Motherboard

|

Abit KT7A - Modified for the test

|

|

Video card

|

Gainward - Cardex Twinview GF2 MX 32mb

|

|

Nic

|

Netgear FA310TX

|

|

Hard Drive

|

WD 40GB 7200RPM

|

|

PSU

|

Enermax 651

|

|

Thermal Gear

|

ExTech Dual Probe Thermometer,

RayTech IR Temp Gun

|

|

|

|

|

|

After every mounting and remounting of the HSF's The thermal paste will be cleaned from the top of the core and from the block and a new application

will be put on. We are using all ASII and all from the same batch.

|

|

|

Test Script

|

|

|

|

|

The testing script will be the Test parameters used to bench each HSF. These consist of timing of events, and sequence of events.

|

|

|

|

Sequence of Events:

- (T+0)Data Logging begins - Start Point

- (T+10sec) Testing machine is powered up and left to idle ( pre heat)

- (T+7:10Min) Testing machine initiates CPU LOAD testing for 15 Min. ( Heat Up

- (T+22:10Min) CPU LOAD test ends CPU is left to run at idle for 7 Min. ( Cool Down)

- (T+29:10Min) Data Logging Ends.

|

|

|

|

The total time it takes to test a block is 29 min for 1 test set. Each block will be tested 3 times. The results will be averaged. The tests

will be valid as long as the Ambient intake air doesn't vary by more then 5DegF for more then 1 min. ( a cold or warm draft wont affect the long term test result, but a continued increase/decrease will.)

4 Temps will be recorded for each HSF.

T1 - Ambient T2 - CPU Core T1-T2 The Delta between Core/Ambient. The Motherboard monitor will also be recorded. Data sample time is once every 6 seconds for the MBM app, so we slowed the Extech Data resolution to once every six seconds. Data Logging and results gathering is happening on an independent machine so the logging does not interfere with the CPU LOAD temp testing.

|

|

|

|

|

|

The CPU heat load testing, was done with the "CPU Stability Test v6" which offers a CPU warming facility. From testing it heats the core just

as well as anything else ( Folding, Prime, etc...).

It also offers a timer and stuff that made it easy to use in this test.

|

|

|

|

|

|

|

The Test setup is the same as in previous tests. I am using a KT7A for these tests that has been modified just like the KT7E I was using.

I am keeping the KT7E for the WaterBlock roundup as

|

|

|

|

its been specially prepared to run pelt cooled systems and waterblocks. No need to ruin a board before you can abuse it fully ;)

|

|

|

|

| Random Forum Pic |

|

| From Thread: More homemade blocks: CPU & NB |

|

| | ProCooling Poll: |

| So why the hell not? |

|

I agree!

|

67% 67%

|

|

What?

|

17% 17%

|

|

Hell NO!

|

0% 0%

|

|

Worst Poll Ever.

|

17% 17%

|

Total Votes:18Please Login to Vote!

|

|

Vantec Cu CCK6035D Vs Al FCE 6030D

Vantec Cu CCK6035D Vs Al FCE 6030D